Produktdetaljer

Detaljeret produktbeskrivelse

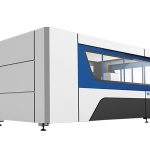

| Skæreområde: | 1500 * 3000mm | Køletilstand: | Vandkøling |

|---|---|---|---|

| Laserkraft: | 1000W | Arbejdsbar maksimal belastning: | 1000kgs |

| Positioneringsnøjagtighed: | ± 0,05 Mm | Transportpakke: | Seaworthy Plywood Case |

| Technical Class: | Kontinuerlig bølgelaser | Ansøgning: | Agriculture Machinery, Automotive Industry, Advertising Industry, Metal Processing |

Produkt beskrivelse

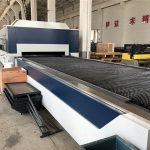

1.The strong frame is completely welded, high temperature annealing and stress relief treatment to ensure no deforming.

2. Imported high precision ball screw transmission / rack & pinion, high precision linear guide rail.

3. Imported servo motor and drive, imported high-rigidity precision gearbox.

Equipped with auto-lubrication device, with dust removal and smoke extract system in cutting area.

4.Modular structure of laser generator, high performance and free from maintenance

Professional laser cutting software, easy, convenient and smart to operate, easily design all kinds of graphics and texts for cutting.

Advantages over Other Cutting Machines

1. The super high photo-electric conversion efficiency can be up to about 30%. So the machine runs with the lowest power consumption compared to other laser cutting machines under the same output power. So the cutting cost is the lowest.

2. With laser beam of good quality from double-clad fiber(DCF), the focus spot is superfine, and the cutting seam is very even and fine. Then the efficiency can be higher, and the quality is better.

3. The surface-area-to-volume ratio (SVR) of the gain medium is big.

4. The light path is totally composed of fiber laser and fiber laser units, which are combined together based on cable splicing technology. And the whole light path is enclosed in fiber laser waveguide.

5. No laser working gas and can start cutting just by blowing air. And fiber optic transmission requires no need of reflector mirrors. In a word, the machine saves maintenance costs greatly.

6. The efficiency is very stable and reliable by adopting the diode pump laser module. No need to adjust the light path. So it’s easy to operate and maintain the machine.

7. Key units have the working life of 100 thousand hours.

8. High output power from 200 to 4000w can be customized.

9. The machine costs little water and energy. And the machine requires no gas. So the running cost is lower.

What Materials Can our Machine Cut ?

| Materiale | Skæringstykkelse (Mm) | Skæring hastighed (M / min) | Skærer gas | Skæretryk | Dyse | Kollimator / fokus |

| Kulstål | 0.5 | 30-40 | Luft | 6 | 1,5 enkeltlag | 75/125 |

| 0.8 | 20-25 | Luft | 8 | 1,5 enkeltlag | 75/125 | |

| 1 | 18-22 | Luft | 10 | 2,0 enkeltlag | 75/125 | |

| 2 | 5-6.5 | Ilt | 3.5 | 1,2 dobbeltlag | 75/125 | |

| 3 | 3-3.5 | Ilt | 0.5-1 | 1,2 dobbeltlag | 75/125 | |

| 4 | 2-2.3 | Ilt | 0.5 | 1,2 dobbeltlag | 75/125 | |

| 5 | 1.5-1.8 | Ilt | 0.5 | 1,2 dobbeltlag | 75/125 | |

| 6 | 1.2-1.4 | Ilt | 0.5 | 1,5 dobbeltlag | 75/125 | |

| 8 | 0.9-1.2 | Ilt | 0.5 | 2,0 dobbeltlag | 75/125 | |

| 10 | 0.7-0.8 | Ilt | 0.5 | 2,5 dobbeltlag | 75/125 | |

| 12 | 0.5-0.65 | Ilt | 0.5 | 2,5 dobbeltlag | 75/125 | |

| Rustfrit stål | 0.5 | 30-40 | Kvælstof | 7 | 1,5 enkeltlag | 75/125 |

| 0.8 | 22-25 | Kvælstof | 10 | 1,5 enkeltlag | 75/125 | |

| 1 | 20-23 | Kvælstof | 12 | 1,5 enkeltlag | 75/125 | |

| 2 | 6-7 | Kvælstof | 15 | 2,0 enkeltlag | 75/125 | |

| 3 | 2.5-2.8 | Kvælstof | 18 | 2,0 enkeltlag | 75/125 | |

| 4 | 0.8-1.2 | Kvælstof | 18 | 2,0 enkeltlag | 75/125 | |

| 5 | 0.6-0.8 | Kvælstof | 18 | 2,0 enkeltlag | 75/125 | |

| Aluminium | 0.5 | 20-25 | Luft / kvælstof | 8 | 1,5 enkeltlag | 75/125 |

| 0.8 | 15-18 | Luft / kvælstof | 9 | 1,5 enkeltlag | 75/125 | |

| 1 | 10-12 | Luft / kvælstof | 12 | 1,5 enkeltlag | 75/125 | |

| 2 | 3-3.5 | Luft / kvælstof | 18 | 2,0 enkeltlag | 75/125 | |

| 3 | 1-1.5 | Luft / kvælstof | 18 | 2,0 enkeltlag | 75/125 | |

| Messing | 0.5 | 22-30 | Kvælstof | 12 | 1,5 enkeltlag | 75/125 |

| 0.8 | 13-17 | Kvælstof | 12 | 1,5 enkeltlag | 75/125 | |

| 1 | 10-12 | Kvælstof | 15 | 1,5 enkeltlag | 75/125 | |

| 2 | 2-3 | Kvælstof | 18 | 2,0 enkeltlag | 75/125 | |

| 3 | 1-1.3 | Kvælstof | 18 | 2,0 enkeltlag | 75/125 | |

| Kobber | 0.5 | 15-18 | Ilt | 12 | 1,5 enkeltlag | 75/125 |

| 0.8 | 8-12 | Ilt | 12 | 1,5 enkeltlag | 75/125 | |

| 1 | 5-7 | Ilt | 12 | 1,5 enkeltlag | 75/125 | |

| 2 | 0.8-1.2 | Ilt | 15 | 2,0 enkeltlag | 75/125 |

Anvendte materialer i 1000W fiberlaserskæremaskine

Fiberskærer bruges hovedsageligt til kulstofstålskæring, blødt stål, rustfrit stål, siliciumstål, aluminiumslegering, titanlegering, galvaniseret stålplade, picklingplade, aluminiumszinkplade, kobber og mange slags metalmaterialer. Det er en cnc-laserskærer, der kan bruges til at skære høj præcision. Det kan også kaldes fiberskæremaskine, fiberoptisk laserskærer, laserskærer til metal, fiberskærer, kulstofstålskæring, cnc laserskærer.

Teknisk parameter

| Arbejdsområde | 3000 * 1500mm |

| Controller + Hejefølger | Cypcut |

| Laserkilde | Fiberlaser kilde 1000W |

| Bølgelængde | 1070nm ± 10nm |

| Laserhoved | Valgfri |

| Gear og rack | Tyskland |

| Guide Rail | Taiwanesisk HIWIN |

| Positionering af præcision | ≤ ± 0,04 mm |

| Skære tykkelse | 1-12mm |

| Maksimal skærehastighed | 40000mm / min (ifølge materialer) |

| Arbejdsspænding | AC220V / 110V ± 10% 50 HZ / 60 HZ |

| Min linje Bredde | ≤0.12mm |

| Transmission | Yaskawa servo 850W + FASTON reducer |

| Z-akse | Yaskawa 400W + bremse |

| Køling | Vandkøling |

| Struktur | 10mm tykkelse svejset stålrør, aluminiumslegering |

| Strømforbrug | ≤7.5KW |

Applied Industry of 1000W Fiberlaser-skæremaskine

Denne laserskærer til metal anvendes i metalbearbejdning, luftfart, rumfart, elektronik, elektriske apparater, metrodele, bil, maskiner, præcisionskomponenter, skibe, metallurgisk udstyr, elevator, husholdningsapparater, gaver og håndværk, værktøjsforarbejdning, udsmykning, reklame, metal udenlandsk forarbejdning forskellige fremstillingsindustrien.