Produktdetaljer

Certificering: CE / FDA

Betalings- og forsendelsesbetingelser:

Minimum ordremængde: 1 SET

Pris: USD pr. SET

Emballeringsdetaljer: Trækasse med jernbindebånd

Leveringstid: 20-30 arbejdsdage

Betalingsbetingelser: T / T, L / C, Western Union

Forsyningsevne: 2000 enheder om året

Detaljeret produktbeskrivelse

| Lasertype: | Fiberlaser kilde | Skæreområde: | Diameter 20-200mm |

|---|

| Køletilstand: | Vandkøling | Ansøgning: | Anvendeligt materiale |

|---|

| Arbejdsspænding: | 380V / 50Hz | Fokusmetode: | Følgende og automatisk justere fokus |

|---|

| Transmissionsmetode: | Gear og rack | Laserkraft: | 500W 1000W 2000W 4000W |

|---|

| Arbejdsbar maksimal belastning: | 1000kgs | X / Y Axis Positio: | 0,05 / 1000mm |

|---|

| Skærehastighed: | 0-60000mm / min | klasse: | Klasse 4 Laser |

|---|

Produkt beskrivelse

| Lasertype | Fiberlaser |

| Lasermærke | IPG / Maxphotonics |

| Laserkraft | 500W (1000W / 2000W / 4000W valgfri) |

| Arbejdsområde | 1500mmX3000mm 1300x2500mm Valgfrit |

| Arbejdsbord | Fast arbejdsbord |

| Kontrolsystem | PMAC servostyring med fuld lukning |

| Kørselstilstand | Dobbelt gearkørsel |

| Tomgang / behandlingshastighed | 72 m / min / 36 m / min |

| Positioneringsnøjagtighed | 0.05mm |

| Beskyttelsessystem | Kapslingsbeskyttelse |

| Laserhoved | Precitec / Laser Mech |

| Strømforsyning | AC220V ± 5% 50 / 60Hz / AC380V ± 5% 50 / 60Hz |

| Total styrke | 7KW ~ 11KW |

| Gulvplads | 5,6mX3,2 m (fast tabel) |

| Standard kollokation | Metalindlejringssoftware, gas med to tryk i 3 slags gasskilder, dynamisk fokus, fjernbetjening osv. |

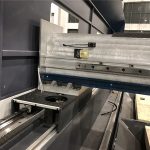

Specifikation for skæringsrørdetaljer

| Skærelængde | 6000mm |

| Diameter | 20mm-200mm |

| Min resterende materiale | 250mm |

| X-akse | 230mm |

| Y-akse | 6500mm |

| Z-akse | 175mm |

| Position nøjagtighed | 0.05mm |

| Reposition nøjagtighed | 0,03 mm |

| Maksimal bevægelseshastighed for X-aksen | 40m / min |

| Maksimal bevægelseshastighed for Y-aksen | 500mm / s |

| Acceleration | 1 G |

| Størrelse (L * W * H) | 12000 * 1800 * 2400 mm |

| Vægt | 3800 kg |

Fordel

1) Advanced performance for different shape of tube

It can meet the demand of round tube, square tube and other profiled tube processing.

2) Different cutting shape

All kinds of graphics cutting can be done for the square tube.

3) Special shape cutting for round tube

Square hole, waist shaped hole made for round pipe.

4) Without no cutting slag

With special slag receiving process, guaranteeing no slag left inside of wall.

5) Specific fixture customized

Different requirement of fixture can be customized according to customer's demand.

6) Powerful computer system

With good nesting software and CNC system, it is simple and easy to learn for operators, improving materials utilization and reducing cost.

7) Clean cutting and environmentally friendly.

With advanced exhaust systems, it is easy and convenient to collect the waste materials during the cutting.

8) Customized design

Effective tube length can be customized from 100-6000mm.

9) With auto-loading and auto-unloading device

The material auto-loading and auto-unloading device can be integrated in the tubing machine, which improve the efficiency and reduce the workload greatly.